1. Oil and Gas Industry:

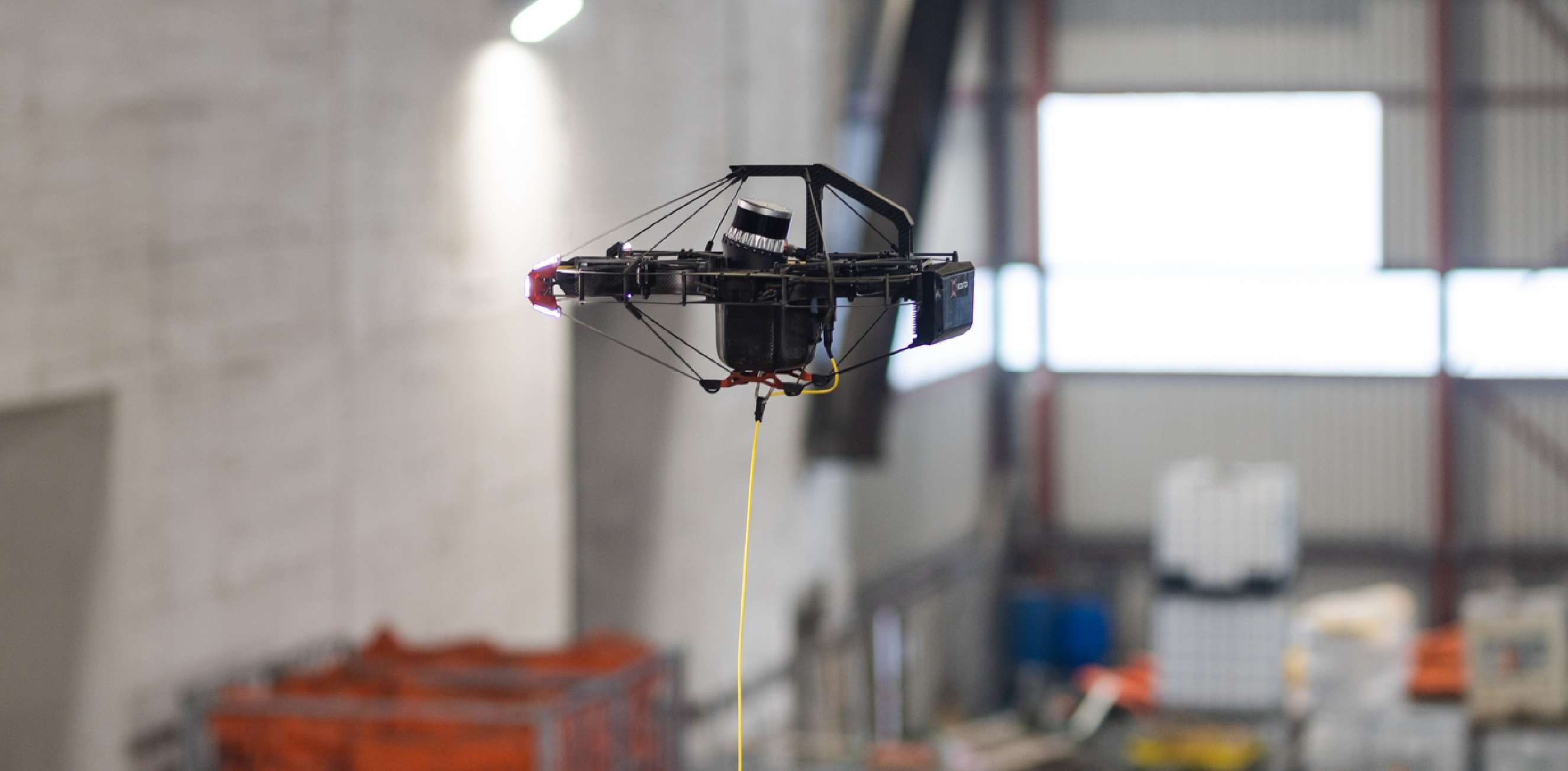

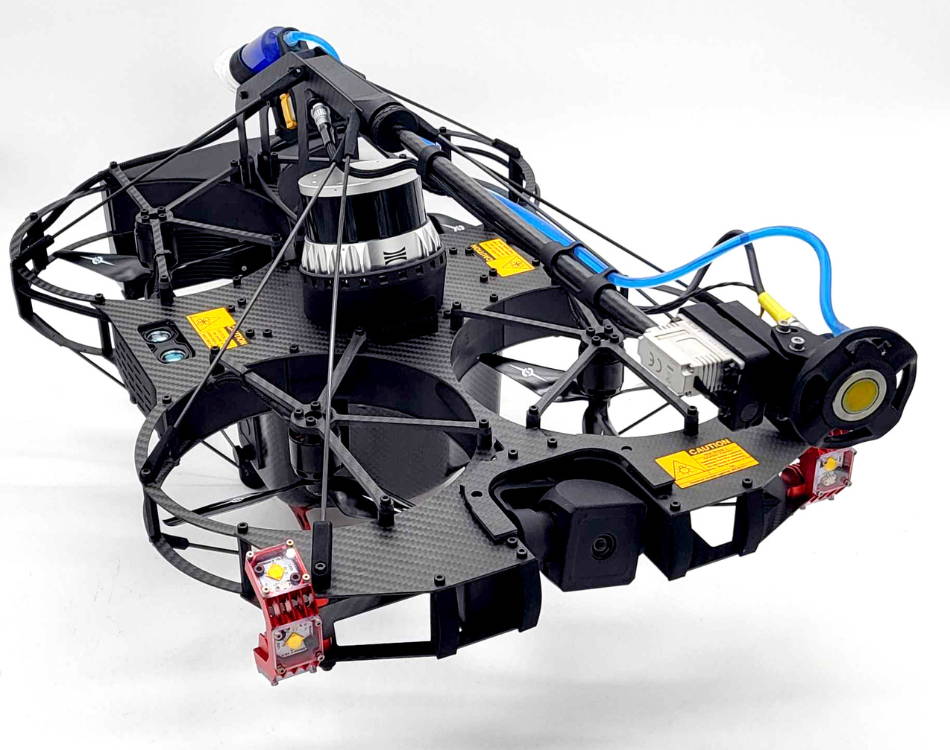

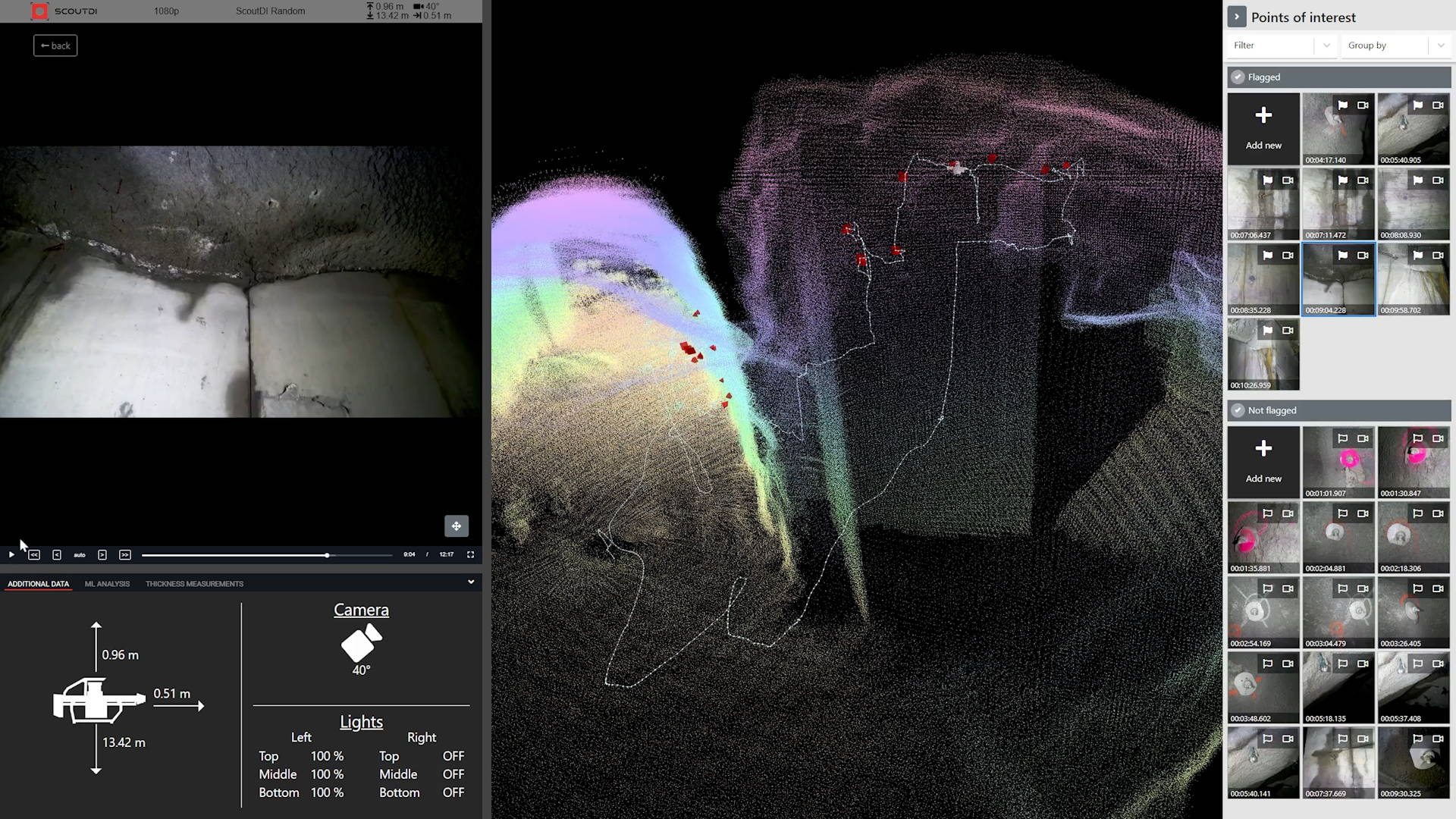

Pipeline Inspection: Conducts thorough inspections of pipelines, detecting corrosion, leaks, or structural damage without requiring human entry into hazardous environments.

Tank Assessment: Inspects storage tanks for cracks, leaks, or integrity issues, ensuring compliance with safety regulations and preventing potential environmental hazards.

2. Manufacturing Sector:

Equipment Inspection: Surveys machinery and equipment in manufacturing plants, identifying defects or wear and tear that could lead to downtime or production delays.

Structural Integrity Assessment: Evaluates the structural integrity of manufacturing facilities, including beams, columns, and other structural elements, to ensure workplace safety and compliance.

3. Construction Industry:

Building Inspection: Surveys building interiors for structural assessments, identifying potential issues such as cracks, leaks, or inadequate support structures during the construction phase or for ongoing maintenance.

Safety Inspections: Conducts safety inspections of construction sites, identifying hazards or compliance issues to prevent accidents and ensure worker safety.

4. Utility Sector:

Infrastructure Inspection: Inspects utility infrastructure components in hard-to-reach areas, ensuring reliability and preventing power outages.

Facility Maintenance: Facilitates routine maintenance inspections of utility facilities, detecting issues early to prevent costly downtime and equipment failures.